About TellRight

The printing proofreading errors always cause problems for printing press and enterprises. There are tiny mistakes that is hard to detect with naked eye during each step of processes.

Open file—Review—Bleed—Conversion—Layout—RIP—Proofing—CTP—Printing—post-press finishing

Risk of errors may occur in any step, that makes proofreader needs to confirm over and over to ensure that the printed product is consistent with the customer's file. Enterprises also know the risks of misprint, so they must check the printing proof and printed sheets carefully. However, after lots of time and energy spend on proofreading, mistakes still happen. It will cause losses to enterprises and printing press.

Therefore, EAB Technology has developed TellRight solution to reconfirm at different stages. From file inspection to printing material receiving, you can find suitable products!

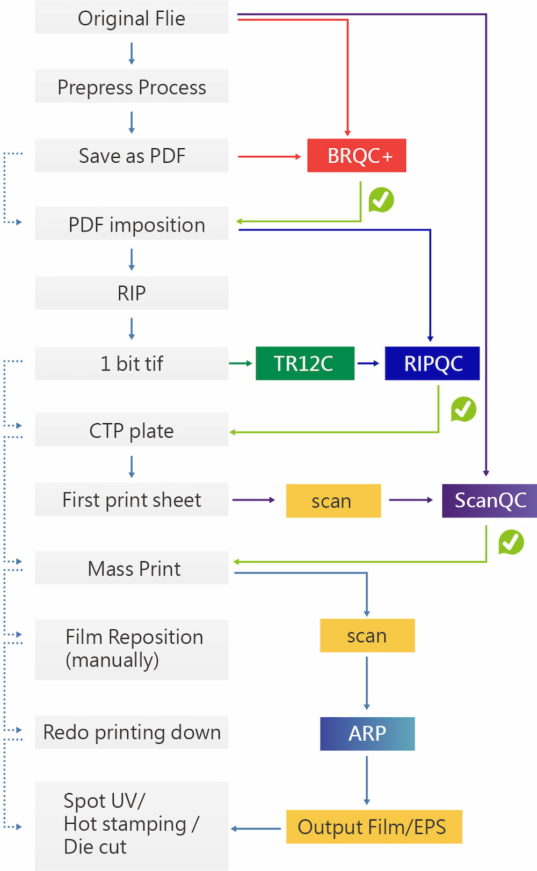

TellRight QC Workflow

TellRight workflow

Traditional workflow

BRQC +

BRQC Plus is applied in inspection of preRIP files. It can check all the differences between the original file and the edited file, such as packages, books, labels, etc.

RIPQC

RIPQC is applied during inspection of files postRIP. It's developed to solve the problem that is difficult for CTP to proofread and to insert an inspection checkpoint into the existing process.

TR12C

TR12C needs to be use with RIPQC. It can help user to converts the ripped image (1-bit TIFF format) to the compose contone TIFF.

ScanQC

ScanQC is the final checking step before the first print. You can check the "first printed sheet" with "original file" for final confirmation to avoid the misprint of large quantity. It is also use for printed products receiving inspection.

ARP

ARP is a solution for post-press finishing. It was designed to check the position of areas which was reserved for spot UV, hot stamping, die cut etc., It can relocate the position and output the correct film or EPS file.